Unpowering Robotics secures $ 8.5 million to help clients find the right automation technology

Pedic Crude Internationally, € 8.5 million has closed an extended fund to scale one of the largest obstacles to automation: makes it easy to handle robots through the intelligent software.

Round was supported by Dirtisma Growth Partners, Navivo Capital, Future Industry Ventures, VENT.IO and D1 Z.

“We have hit a splendor with SMEs: Each one is looking for simple and affordable automation solutions without the need for special skills that can be applied quickly,“Co-founder says MulsevicThe

Kevin Freys and Mladen Millisevic founded Unchanded Robotics in 2019. Individual automation platform clients enable clients to find the right automation technology for their manufacturing processes. Its offer includes individually configurable solutions as well as the turkey system with unified software.

According to crude robotics, automation is often complex, expensive and difficult to adapt to existing activities. Robots usually need to be manually programmed, often it takes a few weeks before they launched. For many small companies, this is a big obstacle. The crude robotics shows it to change it.

With its software Luna OS, Unchand Robotics has introduced a standard control system that integrates robots from different manufacturers to the manufacturing environment – such as operating systems for factory robots, easy to use as smartphones.

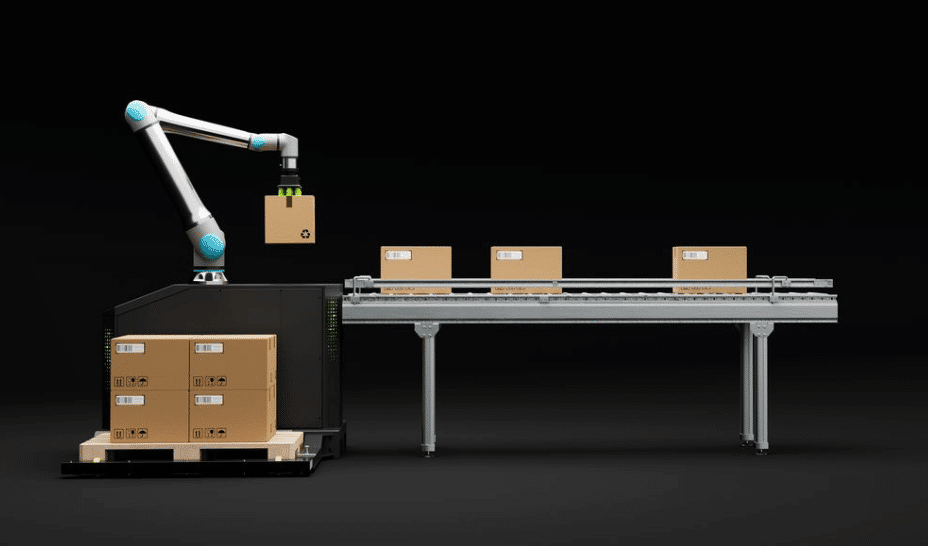

Their online platform agencies allow the right robots to search, find and integrate the right robots directly on their manufacturing lines. Whether it is paletizing or packaging – the company also provides a flexible turkey solution called malorbot, which can be deployed without special knowledge.

More than 300 companies across Europe already use the solution – with names like Vobeswork, the largest direct sales company in Europe. “The solution of crude robotics allows us to quickly and easily automatically — without any additional programming skills or long ramp-up time,” JorneManaging Director or Vorwork Logistics.

In addition to its presence in Europe, obsolete robotics are now accelerating its expansion in the United States throughout several locations, the company is launching its first largest automation partnership with the Albiya Group, the top manufacturers of cosmetic packaging. Automation will include packaging and palettening – including the goal of gaining OPEX skills and increasing the scleibility of local activities.

More than 20 robots have already been deployed in the factory with a plan to increase the number in the future.

“Crude Robotics is solving one of the main structural problems of the industry: a lack of renaming. Robotic automation, including its operating system Luna OS and Modular Malotcharbot Cell, becomes easily scalbled – an important step for the future of production and supplies“, Say Christopher Hoffman Lead the Deriteitima Growth Partners, investors in the current financing round.

According to a Stepston survey, about 1.7 million workers will leave the German labor market by 20. Unchanded robotics believe that automation will be essential for keeping the business competitive – especially in manual functions such as machine loading or paleting.

“We imagine a future where the AI-powered robotic systems not only adopt repetitive acts but become increasingly adapted through continuous education. Luna OS forms an important bridge between intelligent software and physical automation for this purpose,” Kevin FreesCo-founder of crude robotics.

[publish_date